Digitalization and productivity at the service of industry

Digitalization and productivity in industry are closely related. Digitalization is the integration of various digital technologies into industrial operations, transforming the way companies operate and deliver value to customers, or, in other words, improving productivity in industry. One of the key aspects of digitalization aimed at improving productivity in industrial companies is the reduction of

- Published in ZN__News

Digital transformation

In industry, digital transformation consists of applying different technological solutions that respond to specific needs. In this third and last post of a series of three, from Zerintia Technologies we want to share again and in a simple way, different needs that our customers have been having and industrial technology that we have provided to

- Published in ZN__News

Professional video call software

At Zerintia Technologies we offer you a professional video call software through a free trial of our remote support solution, which will allow you to resolve incidents faster and with the highest guarantee of professionalism thanks to its high security standards and image quality. Improve with Zerintia Technologies’ remote support solution the efficiency of technical

- Published in ZN__News

Remote PRL inspections

Acciona is a Spanish company that is part of the Ibex 35 specialized in the promotion and management of infrastructure and renewable energies, with a presence in 65 countries on five continents. The company works intensively on occupational risk prevention, with a specific strategy to respond to legal requirements and to involve the entire organization

- Published in ZN__News

Industrial Technology

Technological solutions for industry are many and varied, so the most important thing is to identify those that respond 100% to specific needs. In this second post of a series of three, at Zerintia Technologies we want to share again and in a simple way, different needs that our clients have had and industrial technology

- Published in ZN__News

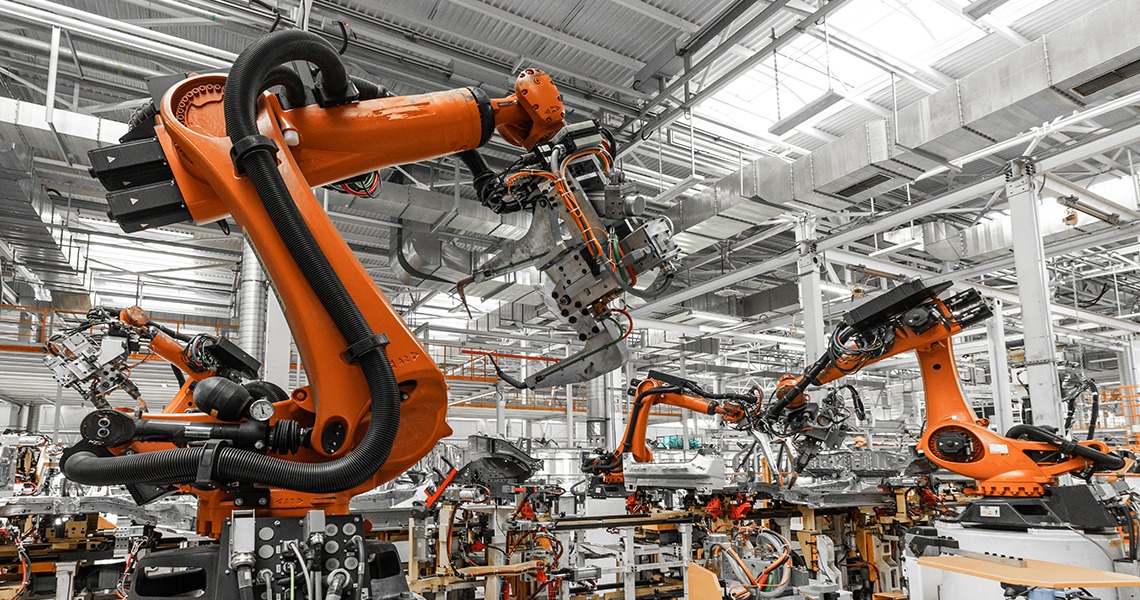

Industry 5.0: revolution or evolution? Collaboration between people, machinery and sustainable development

Una revolución suele implicar un cambio significativo y abrupto en el panorama industrial, mientras que una evolución sugiere una progresión gradual o un perfeccionamiento de las tecnologías y prácticas existentes. Diversos estudios defienden que el emergente concepto de Industria 5.0 consiste en una evolución de la Industria 4.0, complementando tecnologías como la IA, el IoT

- Published in ZN__News

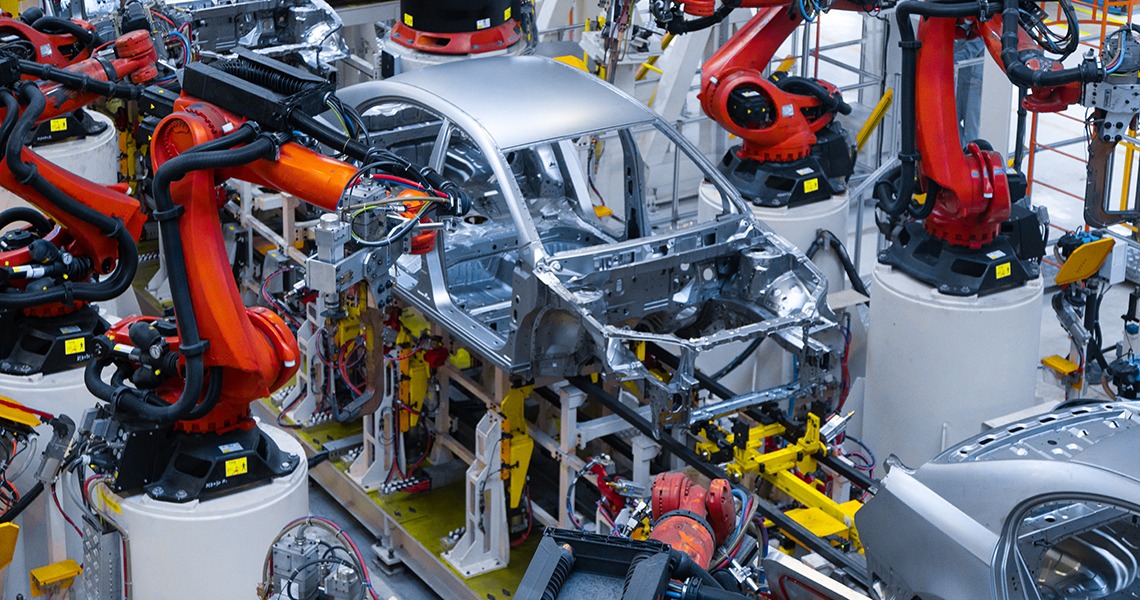

Artificial Intelligence in Automotive

Artificial intelligence (AI) has become a key technology in the automotive sector. According to the Research Institute Mordor Intelligence,the market for Artificial Intelligence in Automotive is expected to reach $16.2 billion by 2026. A continuación, detallamos algunas reflexiones interesantes de Continental Automotive, cliente de Zerintia Technologies, que reconoció desde el principio la inteligencia artificial como

- Published in ZN__News

Technological solutions for industry

The technological solutions for industry are many and varied, so the most important thing is to identify those that respond 100% to specific needs. In this first post in a series of three, from Zerintia Technologies we want to share, in a simple way, different needs that our clients have had and the solutions we

- Published in Uncategorized, ZN__News

Why use 4Manufacturing? Advantages, functionalities, and differences with other systems

The digitization of industrial operations is achieved by integrating management systems (IT), industrial computing (OT) and the connected employee on the same technological platform, thus providing all the advantages of the Connected Industry. Zerintia Technologies’ 4Manufacturing allows you to organize and plan your plant’s manufacturing in an automated way, as it optimizes performance by integrating

- Published in ZN__News

What is Industry 5.0?

Recently, the European Commission (EC) published a report entitled “Industry 5.0 – Towards a sustainable, human centric and resilient European industry“, in which it explains that between 2009 and 2019, the industrial sector accounted for 20% of the European Union’s GDP. In order to face the economic, political and social challenges, industrial companies have been

- Published in ZN__News

Why use 4Aftersales? New services to offer with your machinery

4Aftersales is a Zerintia Technologies solution for machinery manufacturers and distributors to offer their customers new services, while reducing their maintenance costs and generating new direct or indirect revenues. Your equipment with complementary services of rapid deployment and impact that allow you to accompany your customer at all times and anticipate their needs, make offers

- Published in ZN__News

The importance of deploying software under strict security protocols

The secure deployment of software, under strict security protocols, is becoming a mandatory feature in today’s digital landscape. The reasons, though obvious, are many and varied, which is why technology companies invest in their ability to deploy their solutions under your customers’ cybersecurity rules: Data protection: secure software deployment ensures that sensitive user data is

- Published in ZN__News

Human Centric in Industry

Human Centric Industry context focuses on the design of solutions, processes, systems and environments that prioritise the well-being, safety and productivity of the human workforce. This approach recognises the fundamental role that humans play in the industrial sector, primarily, and aims to create work environments that support human needs and capabilities. Key aspects of the

- Published in ZN__News

The importance of multi-device software

Multi-device software, designed to work seamlessly across multiple platforms and hardware, is of significant importance in the modern digital landscape. This type of software provides convenience to the user, allowing them to access applications and services across a multitude of devices such as smartphones, tablets, smartglasses, smartwatches or PCs. Multi-device software ensures that users can

- Published in ZN__News

Automated planning and organisation of a production plant

Converting a production plant into a Digital Factory is achieved through the integration and automated management of information from the entire plant, including employees. This digitisation of industrial operations makes it possible to optimise the overall production capacity of a plant thanks to the synchronisation of all the information between departments, avoiding the use of

- Published in ZN__News

Why use 4Remote? Advantages, functionalities and differences with other remote support tools

Remote support consists of communication between two or more people so that one of them can help the other remotely. 4Remote, the remote support tool developed by Zerintia Technologies, allows this communication to be via audio/video with technicians, customers or suppliers, with Augmented Reality tools, saving costs and travel and generating evidence of the work

- Published in ZN__News

Are you looking for a technology supplier or a technology partner?

Although both a technology provider and a technology partner provide similar products or services, there are clear differences between the two depending on their level of involvement, collaboration and the nature of their relationship with the client. Discover the main differences between those who place limits on their commitment and responsibility, versus those who put

- Published in ZN__News

The importance of technology integration in digitalization

Technology integration plays a critical role in the success of digitization initiatives. It is the process of seamlessly incorporating different digital technologies into various aspects of an organization’s operations, strategies and culture. Here are some key reasons that highlight the importance of technology integration in digitization processes: Increased efficiency and productivity: technology integration streamlines processes

- Published in ZN__News

Industry 5.0 and the ‘Human Centric’ approach

The European Commission, through its Directorate-General for Research and Innovation, recently published a paper on how Industry must change its approach and move towards a human-centered, or Human Centric, approach. In it, Industry 5.0 is defined as a new concept, from which a collaborative and co-creative vision of the industry of the future can be

- Published in ZN__News

How to improve OEE and OLE in production?

OEE (Overall Equipment Effectiveness) is the percentage used to measure the productive efficiency of industrial machinery and gives us the keys on how to improve productivity. OLE (Overall Labour Effectiveness) is the industrial productivity indicator used to measure and improve the efficiency of manual processes that do not involve a machine. Digitization of industrial operations

- Published in ZN__News

Keys to Connected Industry

Connected Industry can be defined as “the integration of advanced technologies and digital connectivity into industrial processes to create a more efficient, productive and interconnected manufacturing environment”. It is also commonly referred to as “Industry 4.0”. Connected Industry leverages technologies such as Internet connectivity, data analytics, cloud computing, artificial intelligence, robotics and automation to transform

- Published in ZN__News

How to orchestrate workflows?

A workflow consists of a sequence of steps or activities that must be completed to successfully execute a specific task. These processes describe the actions, responsibilities and deadlines required to carry out a specific job, ensuring that tasks are performed efficiently, safely and in the desired order. Workflow Phases in Industry In an industrial environment,

- Published in ZN__News

Servitization of machinery and equipment

Servitization is a business strategy that consists of offering services linked to a machine or equipment, in such a way that the value of the business can be derived from the commercialization of these services, thus achieving new revenues. Automotive leasing or pay-per-use in technology companies through cloud and SaaS models are existing examples of

- Published in ZN__News

What are remote hands?

The term “remote hands” refers to the provision of a service by experts, with quality and immediacy, through an electronic device (smart glasses, smartphone, tablet or laptop). Remote hands services allow companies to remotely delegate specific tasks to qualified technicians who are physically on site where the work is to be performed. How do remote

- Published in ZN__News

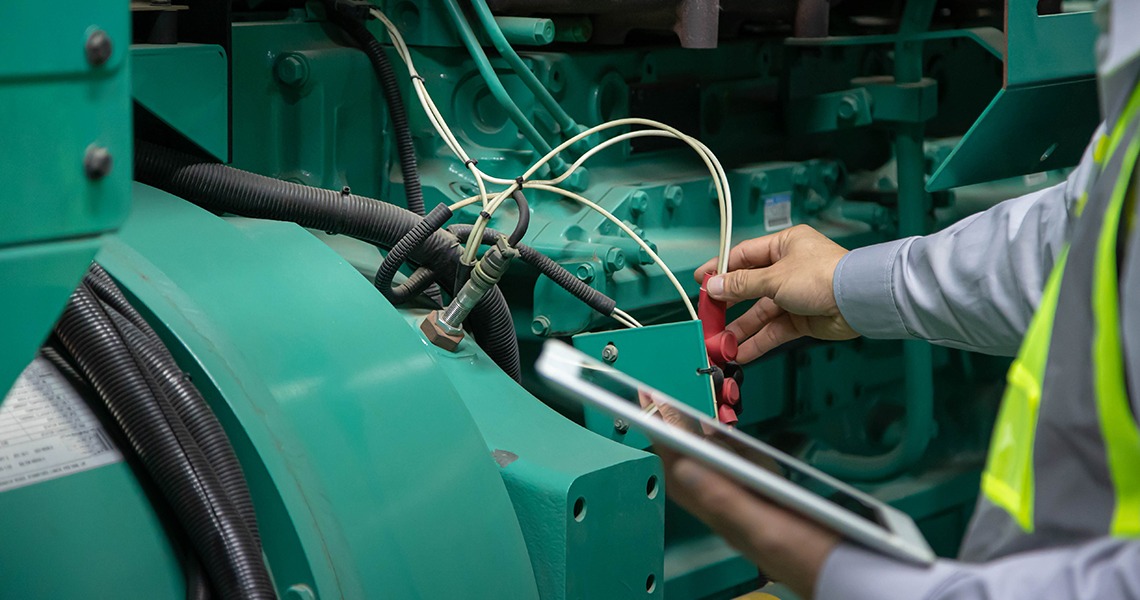

Planned works in Industry

Planned works in Industry refer to maintenance, repairs, upgrades and other activities that are intentionally scheduled and executed to ensure the proper functioning of industrial facilities, equipment and processes. This planned work is essential to maintain operational efficiency, minimize unplanned downtime and optimize asset performance. Preventive maintenance, for example, includes routine inspections, cleaning, calibration and

- Published in ZN__News

Improve your aftersales services in industry and generate new revenues

Improving aftersales services in Industry thanks to digitalization can greatly increase customer satisfaction and streamline any process. Today, Industry 4.0 allows the combination of advanced production and operations techniques with intelligent technologies that integrate the physical, digital and human worlds. These technologies, or what is the same, this digitization, allows the implementation of different business

- Published in ZN__News

Find out how to plan material availability in Industry

In industry, material availability refers to the ability of companies to obtain and access the materials and resources needed for their manufacturing or production processes. It encompasses the availability, accessibility and readiness of raw materials, components, supplies and any other resource necessary for the production or operation of industrial processes. Within the current Industry 4.0

- Published in ZN__News

5 steps for the implementation of your digital roadmap

For industrial companies, it is crucial to design and implement a digital roadmap that will enable them to reach or move towards digitization. This article highlights the 5 steps to follow to create a digital roadmap for an industrial company: 1. Assessment and goal setting: it is essential to assess the current state of the

- Published in ZN__News

How does indoor geolocation work in industry?

Indoor geolocation in an industrial plant makes it possible to determine the precise location of objects or people within a factory’s indoor environment. This type of technology enables real-time tracking, monitoring and management of assets, personnel and equipment within plant facilities. But how does indoor geolocation typically work in a factory? How does indoor geolocationwork

- Published in ZN__News

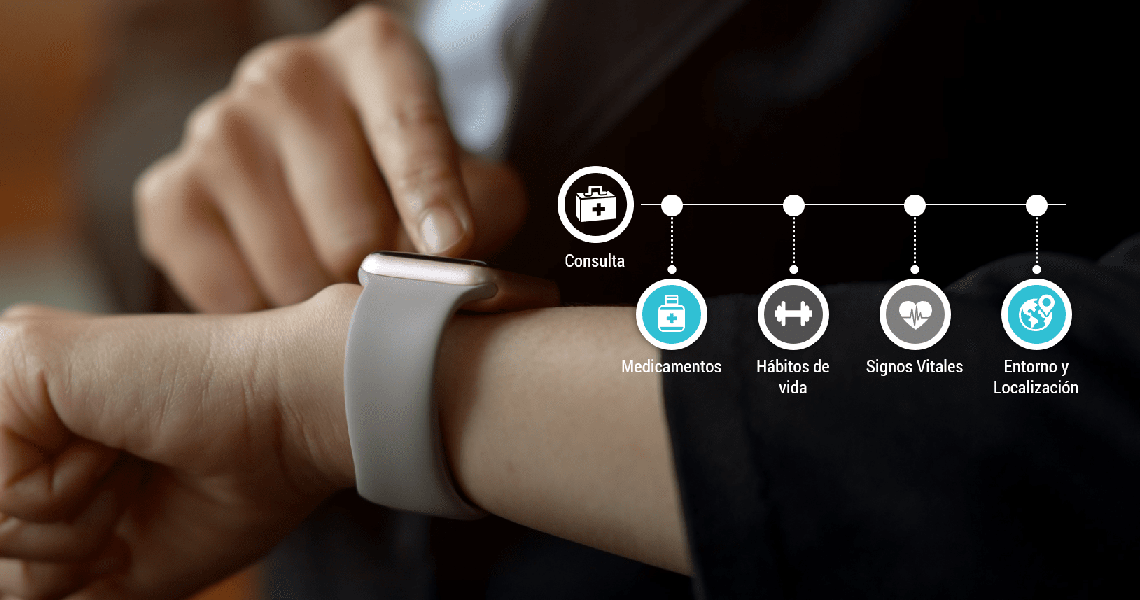

Wearable Technology for the Connected Employee

Wearable technology has the capacity to transform the way workers in the industrial sector operate and interact with their environment. There are multiple examples where the application of these types of devices has had a definite impact over the last few years: – Hands-free: wearable technology, such as smart glasses, enable hands-free working in industrial

- Published in ZN__News

Condition-based preventive maintenance

Condition-based preventive maintenance is a type of maintenance strategy that aims to prevent equipment failure by monitoring equipment condition and performing maintenance only when necessary. This approach is based on the idea that equipment failures are often preceded by specific signs or symptoms, which can be detected by monitoring and analyzing various data points. The

- Published in ZN__News

Picking by vision in logistics

Picking by vision in logistics is a type of order picking process that uses Augmented Reality (AR) technology to assist logistics operators in order fulfillment in the best possible way. This technology involves the use of smart glasses that display visual cues to guide operators through the order picking process. In a typical pick-by-vision in

- Published in ZN__News

5 keys to use Augmented Reality in training

Augmented Reality in training. Augmented Reality (AR) is a technology that superimposes virtual objects on the real world, creating an interactive and immersive experience. Augmented Reality has become an increasingly popular tool for training in a variety of sectors, from Industry to Healthcare. Here are five key ways in which Augmented Reality directly impacts training:

- Published in ZN__News

How to identify bottlenecks in Industry?

Identifying bottlenecks in Industry is essential to increase production efficiency, or in other words, to reduce manufacturing costs, improve product quality and reduce delivery times. The following are the main steps to be taken to identify bottlenecks in Industry: 1. Mapping of the production process. It is the beginning of everything: create a process map

- Published in ZN__News

Orchestration in an industrial plant

The meaning of orchestration is “to organize something, to prepare it in advance without paying attention to other opinions”. In an Industry, this meaning applies in much the same way. Today, thanks to digitalization, all the necessary conditions exist in industry to interconnect different elements, allowing the many existing industrial operations to feed back by

- Published in ZN__News

Time reduction in changeover processes

In Industry, there are multiple procedures that allow to guarantee a good production. Among them are those that allow a wide variety of products to be processed without the need to purchase additional machinery for such operations, something known as changeover processes. Changeover processes are common in Industry where more than one product is manufactured,

- Published in ZN__News

Monitoring employee vital signs

The World Health Organization, WHO, defines occupational health as “a multidisciplinary activity that promotes and protects the health of workers”. It adds: “This discipline seeks to control accidents and diseases by reducing risk conditions”. In other words, occupational health is the employer’s ability to reduce or eliminate any risk factor that may exist in the

- Published in ZN__News

Employee and asset tracking in Industry

The current moment that the industry is living thanks to digitalization allows the traceability of employees and assets with high levels of accuracy. RTLS technology (Real Time Location Systems) makes possible the indoor geolocation of employees and assets (static and in motion): forklifts, AGVs, goods, etc.; while GPS technology enables the outdoor geolocation of employees

- Published in ZN__News

Digitization of production

The digitization of production allows to guarantee the effectiveness in the execution of plant operations, thus optimizing performance and improving the quality of the final product. Through different management systems, it is possible to control the existing information throughout the plant, integrated with other systems such as ERP and other systems, allowing also to monitor

- Published in ZN__News

Why integrate IT-OT systems in Industry?

Industrial companies have multiple systems to provide solutions to different needs. These systems can be of Information Technology (IT), through which they manage product design, manufacturing orders, transport orders or maintenance orders; or of Operation Technology (OT), for the control of physical devices such as PLC, scadas, sensors, etc… In most cases, these systems are

- Published in ZN__News

10 benefits of remote assistance

Our living habits have not been the same since the Covid-19 pandemic. Confinement and restrictions have changed many of our ways of doing things, and our day-to-day lives have been significantly impacted. These changes also affected the way we carried out our work, especially in sectors where the only tools needed are a computer and

- Published in ZN__News

What is the IIoT? Industrial Internet of Things

The Industrial Internet of Things (IIoT) is the use of connected devices in factories to achieve a higher level of automation in industrial machines, which improves efficiency. In a more technical definition, the Industrial Internet of Things (IIoT) is the set of autonomous devices that connect via the Internet to different industrial applications, facilitating data

- Published in ZN__News

Advantages of an unique Technological Architecture

In sectors where digitisation is becoming increasingly important, such as the industrial sector, choosing the right technological solutions to use becomes a fundamental aspect. Not only in terms of efficiency, in terms of using 100% of the software’s power (which is what is contracted), but also in terms of adaptation, taking into account what needs

- Published in ZN__News

The Connected Costumer

Digitalisation in BtoB industrial environments gives us the possibility to get to know our customers better. Technologies such as Remote Assistance, Digital Instructions and the Internet of Things allow us to impact the sales cycle: from product design to after-sales services. For example, an IoT orchestration platform to integrate data and alerts allows us to

- Published in ZN__News

ISA-95 Standard in Industry 4.0

ISA-95 Standard is an international standard that facilitates the integration of all information systems that may be involved in a manufacturing environment, from business functions to plant control systems. This Standard contains standardised models and terminology that can be used by any entity that wants to work on the development of applications, systems and interfaces,

- Published in ZN__News

Industrial plant operations

All companies involved in the industrial sector need to control the operations of their industrial plant in order to, above all, respond proactively and in advance to possible incidents. The way to know what is happening in real time requires the implementation of a plant operations management system, capturing everything that is going on around

- Published in ZN__News

Remote ORP audits

An Occupational Risk Prevention audit is a management mechanism with the objective of reflecting a reliable image of the company’s Occupational Risk Prevention system, assessing its effectiveness and detecting possible deficiencies that could lead to non-compliance with the regulations in force. In this way, decisions can be taken aimed at its improvement and enhancement. An

- Published in ZN__News

What is the EaaS model?

EaaS: Equipment as a Service With the EaaS model, a company specialising in the manufacture of machinery or equipment becomes responsible for maintenance, spare parts and consumables. In this way, it is able to guarantee the availability of this machine or equipment almost 100%, in other words, what its customers actually buy its product for.

- Published in ZN__News

How to improve the occupational health of employees

According to the World Health Organisation, WHO, occupational health is “a multidisciplinary activity that promotes and protects the health of workers. This discipline seeks to control accidents and diseases by reducing risk conditions”. In other words, occupational health is understood as the ability to reduce or eliminate any risk factor that may exist in the

- Published in ZN__News

How to improve the OLE?

The Overall Equipment Effectiveness is the percentage used to measure the productive efficiency of industrial machinery and gives us the key on how to improve productivity. The digitization of industrial operations is the answer to how to improve the OEE by integrating the employee with management systems (IT) and industrial information technology (OT), thus making

- Published in ZN__News

- 1

- 2