Automation of industrial operations

Automation of industrial operations Currently, there are digitalisation solutions on the market that, based on data extracted from previous sensorisation and monitoring, allow the application of configurable rules (conditions) that trigger actions in response to these input events (maintenance, for example), involving employees, machinery and information systems. The main use cases for this type of

- Published in ZN__News

Remote product validation

Product validation is a process that helps us to eliminate any doubts or uncertainties and to ensure that we use resources efficiently to manufacture or develop that product. When it comes to innovation, product validation is a fundamental part of the process, prior to volume production and launch. The market has come to this conclusion

- Published in ZN__News

Industry 5.0: Towards a Human Centric industry, sustainable and resilient European industry

The European Commission’s Directorate-General for Research and Innovation recently published a paper on how Industry should be Human Centric. In this document, Industry 5.0 is defined as a relatively new concept, which provides a basis for further developing a collaborative and co-creative vision of the European industry of the future. Industry 5.0 will be defined

- Published in ZN__News

How to generate new revenues in Industry?

In the Industry, in an Equipment as a Service (EaaS) business model, the machine is provided by the manufacturing company with the addition of a series of digital services that can also be invoiced separately, generating new revenue. Thus, the manufacturer is responsible for maintenance, service, consumables and spare parts, among other services. Even availability

- Published in ZN__News

Digitalization of industrial operations

Industrial operations are a systematic series of processes that can be mechanical, physical or chemical, and that manufacture or produce something at the end of all of them. When a company starts manufacturing a product, the industrial operation is determined by different factors, such as consumer demand, the availability or not of raw materials, the

- Published in ZN__News

How to reduce the execution time?

Industrial processes are a serie of operations of different types: physical, mechanical, electrical, etc. that help to produce a product that is normally carried out on a large scale. In other words, industrial processes are responsible for the mass production of a product from raw materials obtained from different natural resources. For example, the manufacture

- Published in ZN__News

Remote FAT testing

FAT (Factory Acceptance Test) is the process by which a machine or equipment is accepted at the factory. It is a set of standardised, recorded and structured tests performed by machinery and equipment manufacturers after the manufacturing process is completed and prior to shipment to the customer. The purpose of FAT testing is to demonstrate

- Published in ZN__News

Digital end-to-end logistics

Digital end-to-end logistics. Concepts such as picking, kitting or put away are common in the intralogistics sector. Picking, also known as ‘pick and pack’, consists of the preparation of orders using a series of steps that speed up the process. Fundamentally: reception of the order, selection and collection of the elements, packing of the articles

- Published in ZN__News

Condition-based preventive maintenance

La automatización del mantenimiento preventivo basado en condiciones Gracias la digitalización, actualmente existen soluciones tecnologías que permiten llevar a cabo un mantenimiento preventivo basado en condiciones, lo que implica su automatización. Para ello, es necesario contar con mecanismos automatizados que nos permita monitorizar y controlar la máquina o equipo sobre la que debemos llevar a

- Published in ZN__News

Digital customer services

In the Industry, in an Equipment as a Service (EaaS) business model, the machine is provided by the manufacturing company with the addition of a series of digital services that can also be invoiced separately, generating new revenue. Thus, the manufacturer is responsible for maintenance, service, consumables and spare parts, among other services. Even availability

- Published in ZN__News

How to digitise changeovers of format?

In the industrial sector, many of the processes that are carried out are aimed at ensuring the best possible production and improving ROI, so changes and modifications are often made to achieve this improvement in overall performance. Among these processes, one of them is the possibility to produce different products without the need to purchase

- Published in ZN__News

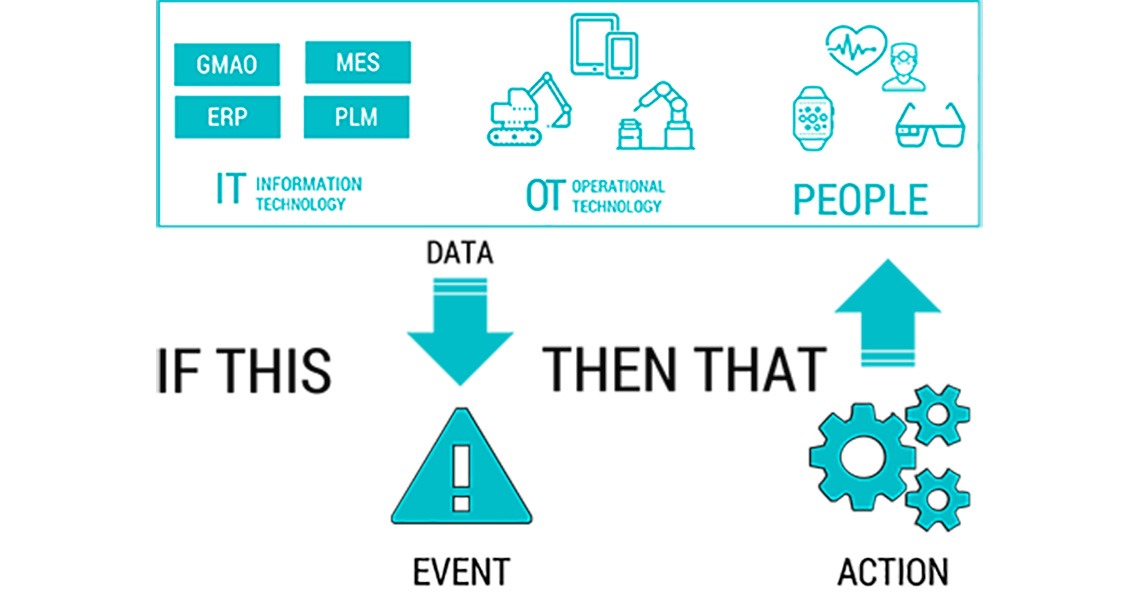

Rules configurator of IoT data

In the industrial sector, an IoT platform connects all assets and integrates all Operational Technology (OT), Information Technology (IT) and employee data from an industrial plant into a single system, so that key events in a process that require an automatic response from the system can be defined, and the system’s responses to those events

- Published in ZN__News

Employee and asset tracking

Today’s technology enables indoor and outdoor geolocation of employees and assets with high levels of accuracy. This technology makes it possible to locate and locate indoors and outdoors in a very precise way. Through RTLS (Real Time Location Systems), indoor geolocation of employees and machinery (static and in movement) is possible: forklifts, AGVs, merchandise, etc.

- Published in ZN__News

Equipment as a Service to the Connected Costumer

Occupational safety is the discipline that, within the Prevention of Occupational Risks, is responsible for the application of the necessary measures for the prevention of risks that may arise from work. In other words, it is the set of techniques and procedures whose result is to eliminate or reduce as much as possible any type

- Published in ZN__News

Digital Occupational Safety

Occupational safety is the discipline that, within the Prevention of Occupational Risks, is responsible for the application of the necessary measures for the prevention of risks that may arise from work. In other words, it is the set of techniques and procedures whose result is to eliminate or reduce as much as possible any type

- Published in ZN__News

Improving the customer experience in Industry

Nowadays, in a globalised world, it is very important to keep our customers happy and satisfied with the product or service we provide. A company is never the only one offering a particular product and service, but there are hundreds of companies in the market with the same characteristics, prices and uses. Therefore, our customer’s

- Published in ZN__News

Production planning

The academic life of a surgeon is long and demanding; a path that goes through different phases: from university, through residency and specialties. In fact, as in most professions, one never stops learning, and the need to keep up to date with new techniques, tools or surgical procedures is 100% recommendable. On the other hand,

- Published in ZN__News

How to digitise quality checks?

Quality control consists of the implementation of processes, programmes, techniques or tools within a company, with the aim of improving the final result of the products it manufactures or the services it offers. In other words, it is about ensuring care and continuous improvement in quality in order to satisfy customers as much as possible

- Published in ZN__News

10 advantages of remote support

The health situation caused by the Covid-19 pandemic changed many of our life habits. Behaviors that we had to modify very quickly that impacted our day to day. Many of these changes also directly affected the way in which we carried out our professional activity, especially in certain sectors where the work tools are a

- Published in ZN__News

What is the connected client?

What is the connected client? New technologies give us the opportunity to know our clients better, be closer and make better decisions as a company. In B2B industrial environments, some of these technologies are the IoT, Digital Instructions and Remote Assistance, which can have an impact on the phases of the sales cycle: from the

- Published in ZN__News

How to improve the OEE?

The Overall Equipment Effectiveness is the percentage used to measure the productive efficiency of industrial machinery and gives us the key on how to improve productivity. The digitization of industrial operations is the answer to how to improve the OEE by integrating the employee with management systems (IT) and industrial information technology (OT), thus making

- Published in ZN__News

Eliminate paper and improve your efficiency: digital instructions for industry

In an increasingly digitized industrial environment, it is still very common to find operators handling forms or check lists printed on paper that are often lost or damaged, and that are intended to be filled in with data that also have to be filled in by hand afterwards in the systems used by the company

- Published in ZN__News

4Manufacturing, much more than a MES system

4Manufacturing is a comprehensive solution by Zerintia Technologies that guarantees the effective execution of the operations of production plants, optimizes performance and improves the quality of the end product. It controls and manages information from the entire plant, including employees, integrated with the ERP and other customer systems, to exchange information and monitor efficiency, detecting

- Published in ZN__News

What is the connected employee? Technologies, characteristics and advantages

The Digital Factory combines the advanced techniques in pruction and operations with smart technologies that integrate the physical and digital world with people. When we speake of people, we refer to employees, who must be the central axis of the Digital Factory’s operations, where all the information they need to carry out their work efficiently,

- Published in ZN__News

New technologies for remotely connected professionals

A recent study by the Bank of Spain, considers that there is ample room to increase teleworking in many sectors. The study analyzes the possibility of teleworking depending on several factors, including the type of work to be done and the degree of preparation of the company to allow this activity to be developed remotely.

- Published in ZN__News

Zerintia and 4REMOTE, Advanced Technology Solutions in Autorevista

4Remote, a success story in the automotive industry

- Published in ZN__News

All in one solution for communication with experts and supervisors remotely, sharing video and audio in real time to solve doubts and incidents or to check the work done. Sharing documents, real-time pointer, drawings and text on video allow operators to be advised in a quick and effective way.

- Published in ZN__News

Remote Assistance with 4REMOTE on Glass Enterprise Edition 2

4Remote’s software can be used on Glass Enterprise Edition 2 to allow professionals to do their jobs more efficiently with hands-free access to the information and tools they need to complete their work. Users can use the Zerintia software on Glass to access checklists, view instructions, send photos and videos, collaborate efficiently, and more.

- Published in ZN__News

ESADE’s Special Digital Transformation

Zerintia has participated, together with other expert companies in new technologies, in the special one on Digital Transformation of ESADE Alumni. Kepa Sagastabeitia, CEO of Zerintia, reflects on the challenges and opportunities offered by the digital transformation in key sectors such as Industry and Health, and the importance of having a digital partner that can

- Published in ZN__News

The Connected Construction in Rocas y Minerales, main magazine in Mining and Public Works sector in Spain

Rocas y Minerales, main publication in the mining, earthworks and public works sector echoes in October our article The Connected Construction.

- Published in ZN__News

Wearbots: The future of communication with our digital environment

We are living a new dawn of Artificial Intelligence (A.I.), mainly associated with concepts such as Machine Learning, Big Data and Chatbots. At Zerintia we are always looking for new ways to interact with wearables and connected devices (IoT devices). We are now presented with a great opportunity across various environments – we can have

- Published in ZN__News

Zerintia reaches an agreement with Vuzix for the development of solutions using smart glasses and augmented reality targeted at the industrial sector.

Zerintia Technologies keeps betting on the digital transformation of the industrial sector, and on advancing towards the smart factory. With this in mind, the company has just entered an agreement with Vuzix® Corporation, one of the world’s leading companies in Smart Glasses, Augmented Reality and Virtual Reality both on corporate and home markets. With this

- Published in ZN__News

Virtual Reality for medical and healthcare environments

Virtual Reality for medical and healthcare environments

- Published in ZN__News

Industrial sector, utilities and Smart Factories manufacturing

Industrial sector, utilities and Smart Factories manufacturing with wearables

- Published in ZN__News

Improving prevention of Occupational Hazards with Wearables

During 2013 there were 468 030 accidents reported in Spain. During 2014 the total number of accidents in time work grew from the previous year -something that has not happened since 2007- by 3.2% and 1.6% in the case of fatal accidents. Our solution to prevent occupational hazards “Occupational Risk Prevention App (ORPA)” allows you

- Published in ZN__News

- 1

- 2