integration and orchestration

Reduce downtimes with automated plant coordination

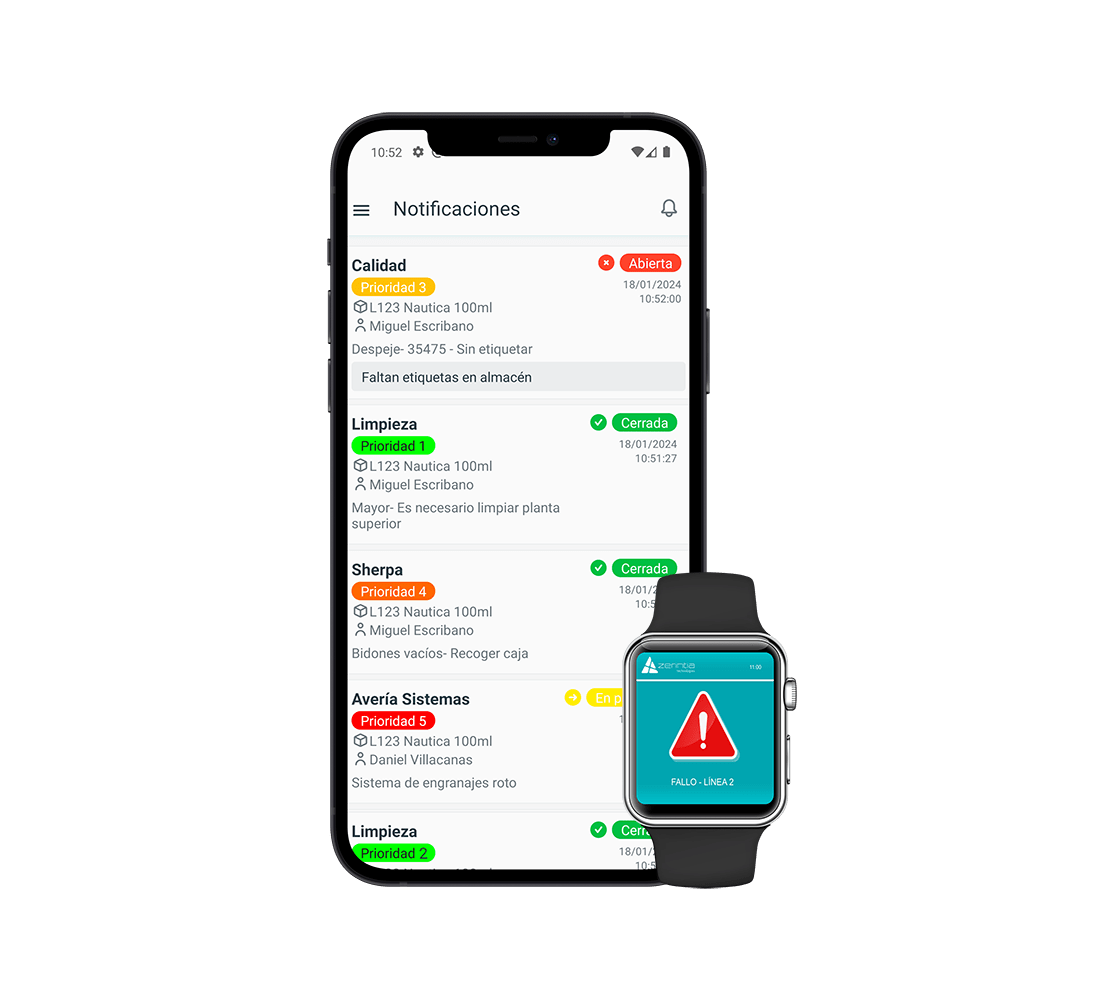

Provide your employees with real-time data to improve the efficiency of workflows in case of incidents or support requests.

Integrate IoT data from your machinery, employees or your own systems into a single platform and easily configure rules and response actions.