Servitization is a business strategy that consists of offering services linked to a machine or equipment, in such a way that the value of the business can be derived from the commercialization of these services, thus achieving new revenues.

Automotive leasing or pay-per-use in technology companies through cloud and SaaS models are existing examples of servitization in these sectors.

However, for machinery and equipment manufacturers, servitization is something relatively new, as until now they have not gone beyond offering a warranty or after-sales service.

Today, customers are not just looking for a product, but for a comprehensive range of additional services that are tailored to their needs. In addition, customers are becoming increasingly demanding and are asking their suppliers to be able to manage the activities that directly affect the machinery or equipment they are paying for.

Levels of servitization in the industry

Principally, there are three levels of servitization in machinery and equipment manufacturing. The three levels are:

– Level 1: provision of products only. Any manufacturer does this today, as it is the ‘core’ part of their business.

– Level 2: after-sales services. This can include any service, from repair to maintenance.

– Level 3: advanced services. May include pay-per-use contracts and integrated solutions.

Advantages of servitization for the customer

A customer with a supplier capable of offering servitization of its product has the following advantages:

– End to the responsibilities of the product they purchase. The supplier manages maintenance and consumption management.

– Long-term relationship. The manufacturer accompanies the customer at all times, extending the relationship and making it difficult to end it.

– Cost reduction and risk reduction for the customer. If the supplier is responsible for the ownership of the products, as well as their maintenance, it helps its customers to reduce the purchase risk.

Advantages of servitization for the manufacturer

Manufacturers thus have a window of opportunity with the commercialization of services:

– Better positioning against the competition by acquiring a competitive advantage.

– Increased recurring and not just one-time revenues, which allows for greater economic and financial stability.

Servitization in the industry

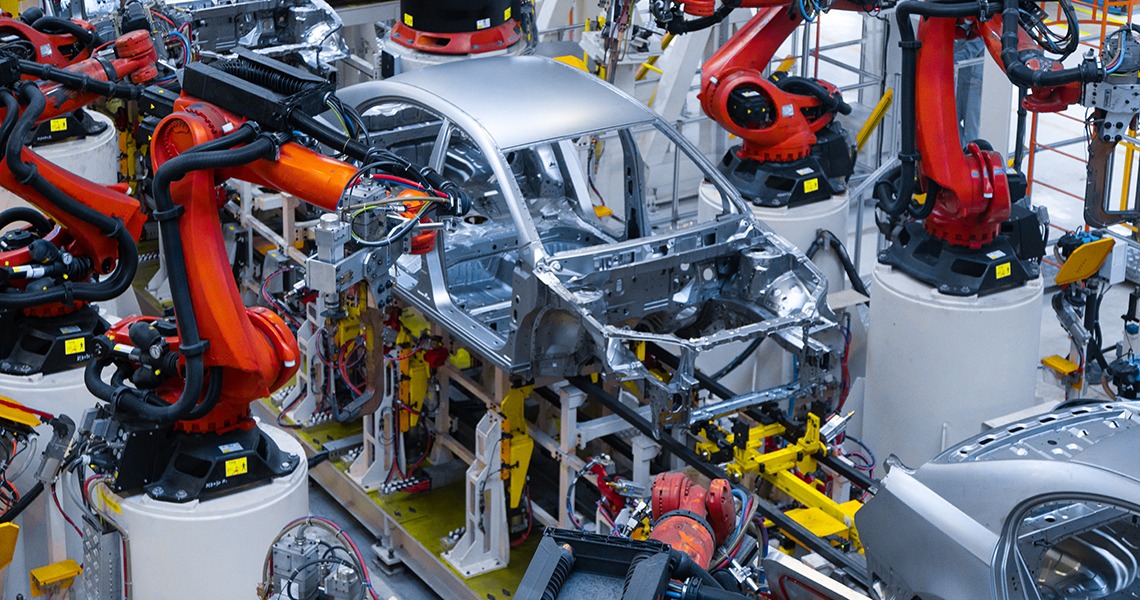

Servitization in the machinery and equipment manufacturing sector requires the successful adoption of technology by the manufacturer.

With monitoring, for example, it is possible to track the performance of a product, as it allows them to effectively analyze behavior. This data informs the manufacturer’s actions, whether it is a repair or a modification to improve product performance.

In order to achieve servitization, manufacturers must adopt the necessary technology.

4AfterSales, the machinery and equipment servitization solution from Zerintia Technologies

4AfterSales is Zerintia Technologies solution that enables the servitization of machinery and equipment, offering a better positioning in the market and the generation of new revenues.