This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

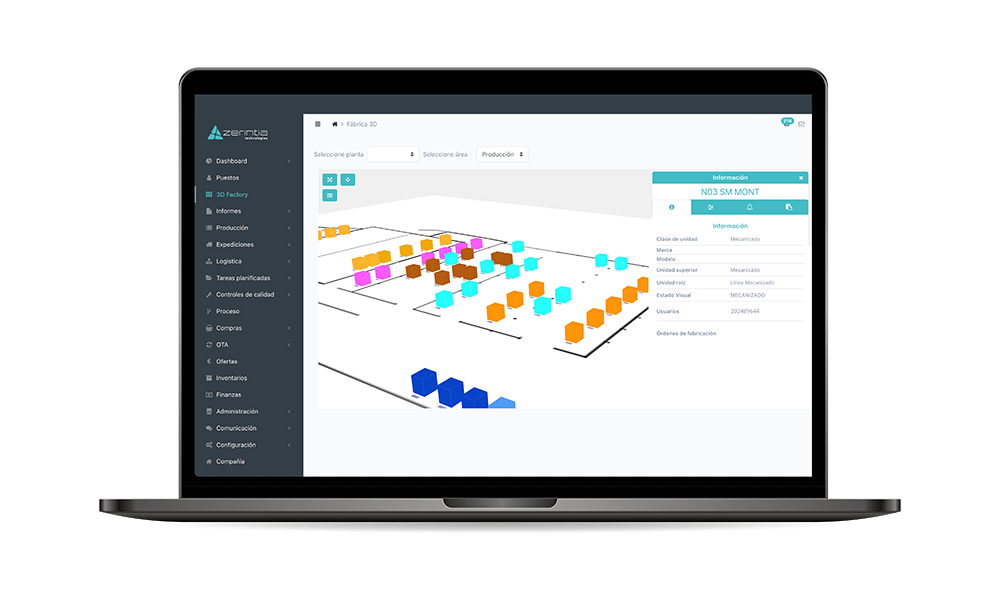

The digitisation of industrial operations involves the integration and automated management of information across the entire plant, including employees. 4Manufacturing turns plants into digital factories, optimising performance and efficiency by digitising processes.

4Manufacturing addresses challenges such as the use of obsolete data, reducing non-operational time and improving the synchronisation of information between departments, which increases the overall productive capacity of industrial plants.

The 4Manufacturing solution is compatible with multiple devices, including PCs, smartphones, tablets, smartwatches and smartglasses. This makes it easy to access information and manage operations in real time.

On PC, 4Manufacturing works through any browser, while on other devices it is necessary to install specific applications, ensuring the flexibility and adaptability of the solution to different work environments.

4Manufacturing is compatible with Mac and iPhone devices, allowing it to be used on a wide range of hardware, facilitating IT/OT integration on the factory floor.

With 4Manufacturing, each company sets up the Privacy Notice according to its internal legal policy, ensuring compliance with data protection regulations and information security.

For detailed information on 4Manufacturing plans and pricing, it is recommended to contact Zerintia Technologies' dedicated team directly. This solution provides a customised approach to meet the specific needs of digital plants and factories.