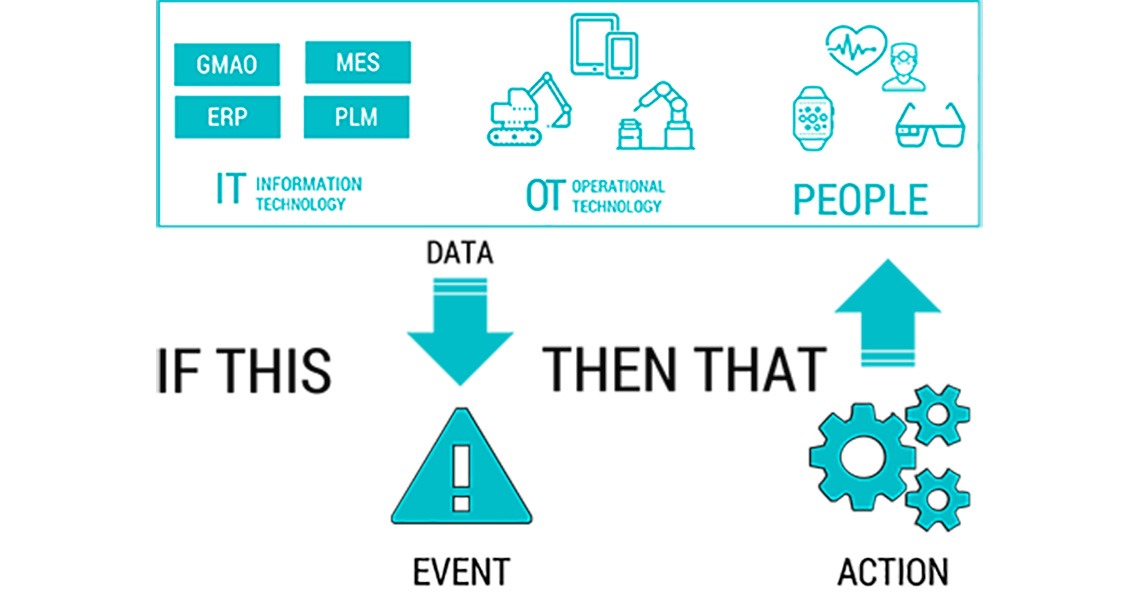

In the industrial sector, an IoT platform connects all assets and integrates all Operational Technology (OT), Information Technology (IT) and employee data from an industrial plant into a single system, so that key events in a process that require an automatic response from the system can be defined, and the system’s responses to those events can be configured in the rules engine.

The use of a rules engine (together with the IoT platform) allows both historical and real-time data to be analysed for proper decision making, facilitating management and establishing priorities that optimise the work of teams and the efficiency of resources.

What actions can be configured with an IoT rules configurator?

The actions that can be configured with an IoT rules configurator respond to the typology of the assets that have been previously integrated into the IoT platform:

Connected employee

– Alerts

– Emails

– Messages

– SMS

Information technology

– Production orders

– Incidents

– Material requests

– Maintenance orders

Operations technology

– Start/Stop

– Open/Close

– On/off

– Signals

4Action, el motor de reglas IoT y plataforma de Zerintia Technologies

4Action es la plataforma de orquestación IoT que contiene el motor de reglas IoT de Zerintia Technologies que integra los datos generados en la planta industrial de distintas fuentes, Tecnologías Operativas (OT) Tecnologías de Información (IT) y empleados, para la detección de eventos en tiempo real.

A partir de dichos datos y la aplicación de reglas configurables, estas desencadenan acciones en respuesta a estos eventos de entrada, implicando a empleados, maquinaria y sistemas de información.

Use cases

Some of the most common use cases where the use of a rules engine and an IoT platform yields the best results are:

– Condition-based preventive maintenance automation

– Automation of corrective maintenance (incidents)

– Monitoring of cadences and queues on production lines

– Integration of alerting systems and Connected Employee orchestration

– Visual states in 3D Digital Twin

– Supply of materials to production

– Physical or virtual buttons to orchestrate actions or workflows