Downtime Reduction in Industry

Founded in 1871, Continental Automotive offers safe, efficient, intelligent and affordable solutions for vehicles, machines, traffic and transportation.

The company is best known for being the world’s fourth-largest tyre manufacturer, ranking third in global sales of OEM automotive parts. Continental Automotive develops pioneering technologies and services for the sustainable and connected mobility of people and their goods and employs more than 245,000 people in 60 countries.

The challenge at the multinational’s production plant

In the past, Continental Automotive employees had to be attentive to their task and to warnings and incidents along the entire line to avoid unnecessary downtime. The company required a solution to improve the efficiency of its equipment and minimize downtime.

For example, if a material ran out at an electronic component placement station, a warning was generated and the operator had to identify it to replenish it as soon as possible, otherwise a line stoppage and consequent loss of productivity would occur.

The installation of screens on the lines to display the alerts was the first measure taken to ensure rapid attention in the event of incidents. However, the system required operators to be constantly attentive to the screen while performing their work, causing distraction from their tasks. In addition, alerts were not prioritized, and resources were not allocated to deal with them, so the final response was uncoordinated.

4Smartworker, la solución de Zerintia implementada en Continental Automotive

Continental Automotive has the 4Smartworker solution, which allows you to connect all existing systems at Continental Automotive, including the plant production control software (MES), machinery logic controllers (PLC) and the native alert system.

With the 4Smartworker Integration & Orchestration tool, each employee has a role based on their job that allows identifying all key events from connected information sources, including the precise location of guided vehicles (AGV).

Before having 4Smartworker, each system generated information independently without any type of evaluation between them. With the implementation of 4Smartworker, all data is integrated, combining information from different sources and becoming an IIoT Platform that integrates the information generated by the industrial plant in a quick, intuitive and simple way.

Based on all the data integrated and received in real time, plant events are identified, which generate alerts, automate workflows and launch concrete actions in response to said events, involving employees, machinery and information systems.

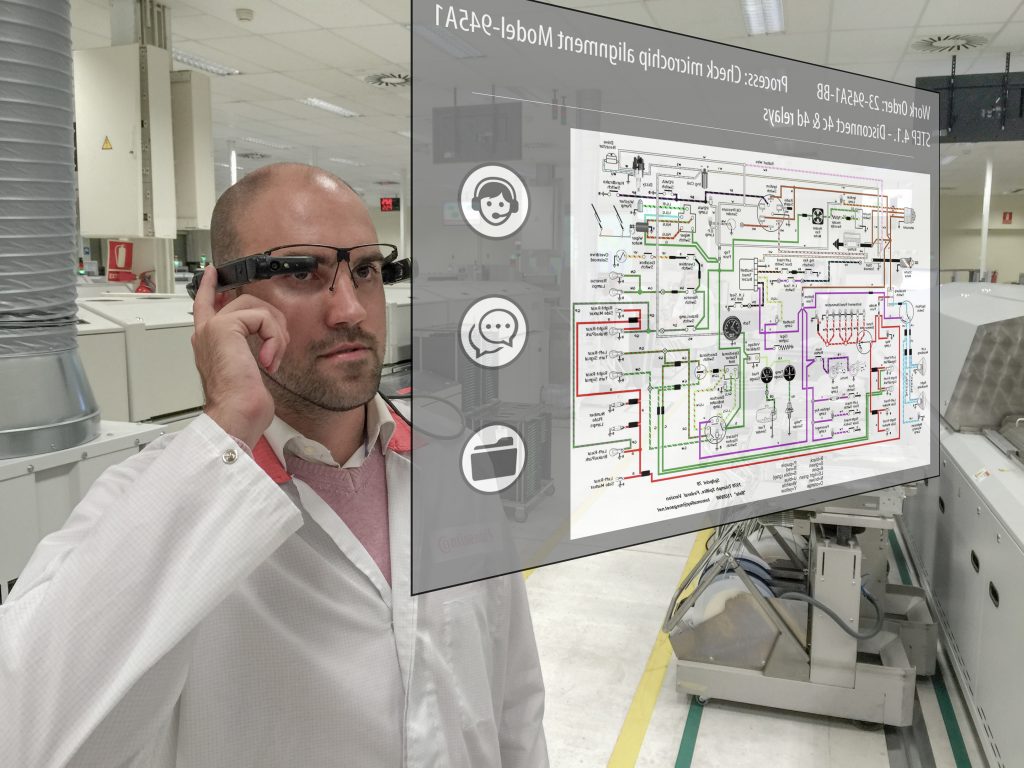

In addition, Continental Automotive has Remote Support and Digital Work tools as a communication platform between plants.

Zerintia, solutions for Industry 5.0

Zerintia Technologies offers B2B SaaS solutions to improve the efficiency of employees and customers, providing advanced tools and services for the digitisation of their operations.

Through our solutions we accompany you in the digitalization of your company in a progressive, flexible and adapted way to your needs.