4Action es una solución de Zerintia Technologies que permite reducir tiempos de respuesta con la coordinación automatizada de una planta industrial.

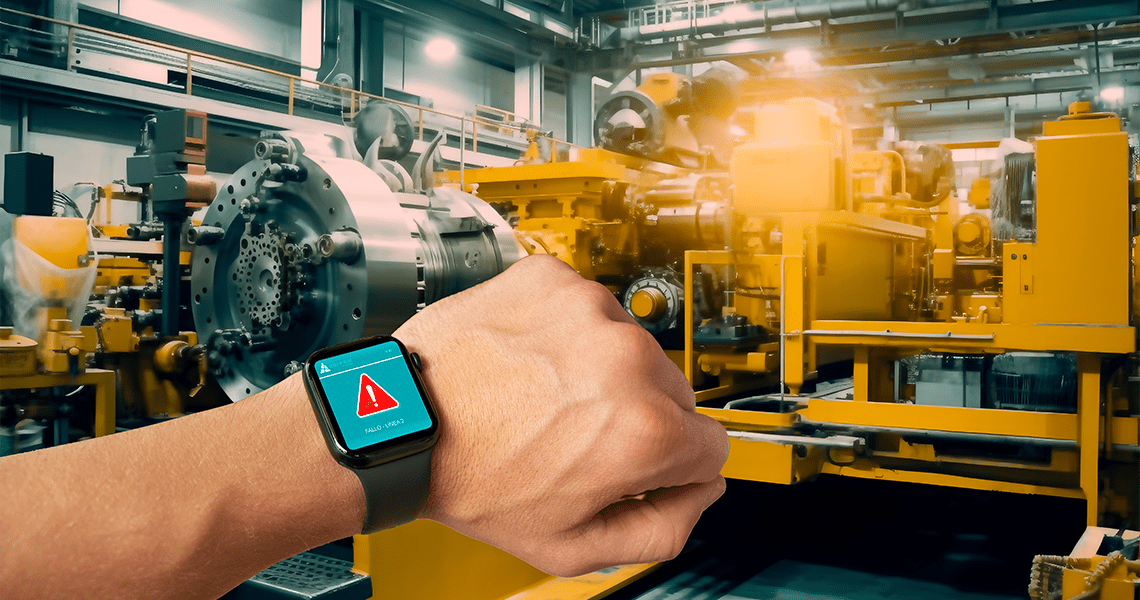

La herramienta proporciona a los empleados de una planta industrial datos en tiempo real para mejorar la eficiencia de los flujos de trabajo ante incidencias o peticiones de soporte.

Además, 4Action permite integrar datos IoT de la maquinaria, empleados o sistemas propios, en una sola plataforma y configurar de forma sencilla reglas y acciones de respuesta.

Plataforma de orquestación IoT para conectar y monitorizar maquinaria

4Action permite también la conexión de máquinas a través de distintos protocolos industriales para monitorizar su funcionamiento y conseguir un rendimiento óptimo. De esta forma, la solución configura avisos de averías, revisiones programadas de maquinaria y notificaciones a técnicos por cercanía en la planta, experiencia o cargo.

Ventajas

• Automatización del mantenimiento preventivo y correctivo basado en condiciones

• Mejora del OEE

• Monitorización de cadencias y colas en líneas de producción

• Suministro de materiales a producción

• Despliegue de botones físicos o virtuales para orquestar flujos de trabajo

• Información en tiempo real

Otras ventajas

• Mayor calidad y disminución de errores

• Integración de sistemas de alertas

• Mejor servicio y soporte al cliente

• Seguimiento y control de recursos y activos

Funcionalidades

• Visualización de alertas en un Gemelo Digital.

• Multi-dispositivo: smartphone, tablet, smartglasses o PC.

• Configuración de reglas sin necesidad de conocimientos de programación.

• Integración con datos IT & OT.

• Asignación de tareas por roles.

• Desplegable en servidores propios o de Zerintia.

• Seguridad de los datos: comunicaciones encriptadas.

• Integrable con sistemas del cliente ERP, GMAO, CRM.

• Integración LDAP.

• Asignación de procesos a elementos ISA95.